Making a Coronavirus Face Mask

31 March 2020

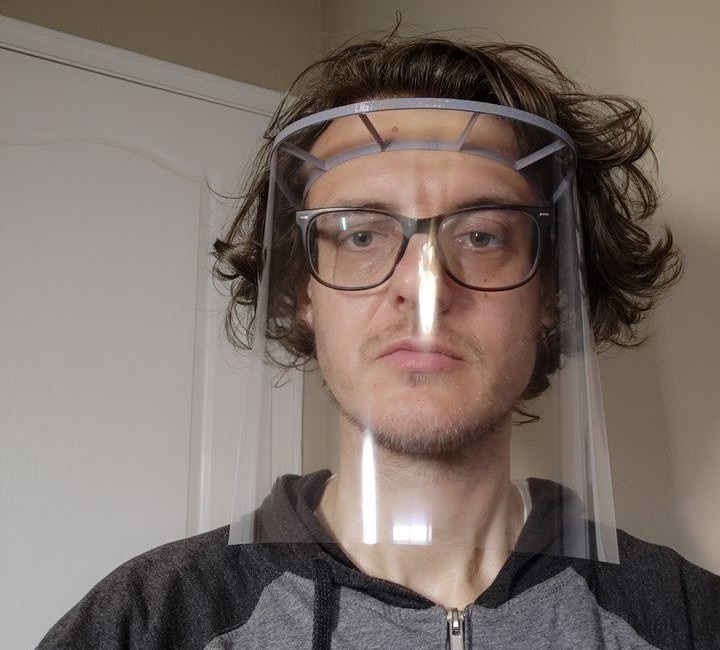

I wanted to design and donate a face mask that satisfied these requirements:

- Low weight (under 20 grams + transparency sheet)

- Low strap tension to prevent discomfort

- Fast to print (under 30 min)

- Robust

- Easy to assemble

- Wraps around the face

- Stays more than 1" away from the nose to prevent fog and discomfort

A comfortable face mask separates my germs from other people's germs.

I believe I was able to hit those due to several design choices:

- The transparent sheet is glued to the 3D printed frame, helping with structural rigidity.

- Frontal shape of two concentric circles with evenly spaced loading bars, making the shape rigid to compression and horizontal shear.

Requirements and Files

- Face shield stl.

- Gluing clamp stl. (optional)

- Printer transparency or transparent binding covers (stronger).

- Trasnaprent all purpose glue. I am using the Go2 Glue with success.

- Elasic head band, approx. 5mm x 1.5mm cross section.

Assembly Process

Steps:

- Sand down the printed surface that will touch the wearer's forehead with fine sandpaper.

- Cut the elastic band in 2 halves. Make one of the cuts where the loop is pre-glued.

- Fold the end of the elastic band and insert into the slot.

- Squirt glue inside the loop and along the slot.

- Squirt a small amount of glue along the transparency guide channel.

- Insert the transparency into the channel firmly and clamp it with the clamps.

- Let it sit for 30 minutes.

- Try it on and if desired, trim the bottom edges with scissors.

The 3 steps above.

The assembled face shield standing on the clamps while the glue hardens.

Printing

Slicer settings are printer-specific, but here is what I used:

Cura Settings

First batch that was delivered to local ER.